Chemical material transportation complete screw systems

Description

Product Description

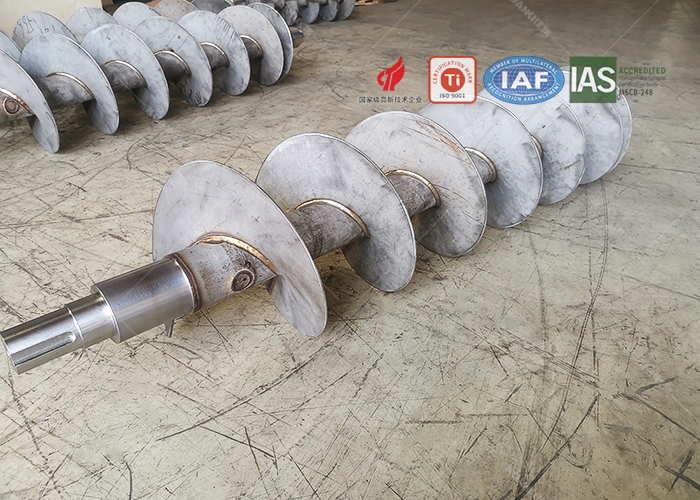

Chemical material transportation complete screw systems is that the rotating spiral blades push the material to be transported by the spiral conveyor, and the force that prevents the material from rotating together with the spiral conveyor blades is the weight of the material itself and the frictional resistance of the spiral conveyor housing to the material. The spiral blades welded on the spiral shaft of the screw conveyor have different surface types depending on the conveyed material, including solid surface type, belt surface type, and blade surface type.

Material characteristics and parameter features reflect:

1. Almost all materials are 3-series stainless steel and duplex stainless steel, such as SUS304L, SUS316L, SAF2205, 10RE51, SAF2507, Ti1, Ti2, Ti3, Ti4, etc. Some are specific stainless steels;

2. The machining accuracy of the entire shaft is high, and the welding requirements are high;

3. The straightening part of the entire shaft cannot be straightened by thermal adjustment;

4. Partial shaft head docking adopts pin docking, spline docking, irregular docking, etc;

5. The spiral blade part will have pitch changes;

6. Ensure the concentricity of the entire axis.

Note: All products can be customized with materials, specifications, and models according to customer's drawings!

The project specific products are measured and evaluated by engineers on-site, and a personalized overall project solution is provided. Long term supply contracts can be signed to improve service guarantee.

Next

最后一篇Send Inquiry